Not too tricky this one, although again lots of careful measuring and double checking. First up was the nose cone, I had read some blogs where people were complaining that the nose cone doesn't fit properly. From what I see GBS changed the design around 2012, it seemed like a few people may have been given old stock with their kits in 2013 so I wasn't sure if my (2014) kit would have the new design; I was 90% sure it would(it did). I had to cut a small piece out of the side to "stretch" the nose over the pre-fabricated tab to attach to:

I wasn't sure if the tab needed to go in front or behind the GRP, other blogs suggest behind and after trial fitting the bonnet and posting on the forum - I decided to cut a notch out so I could get the tab behind the GRP.

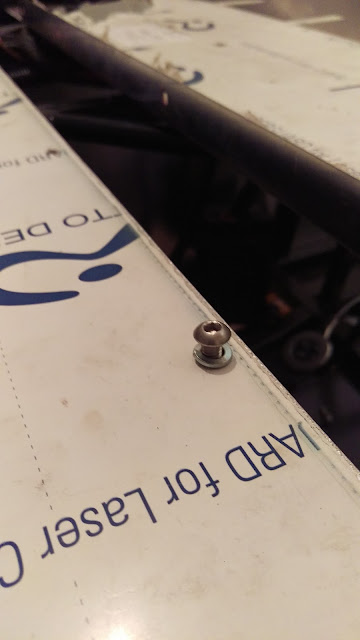

I only purchased two bonnet latches, not sure why I did that.....but I need two more! For now though I made a template to attach to the bonnet and chassis whilst strapped on:

And after attaching my bonnet locator pins here is the result:

I am going to try something different with the rear, I may even adjust these slightly (not entirely sure how I am going to do that though - I may have to leave a hole on the bonnet but that will be hidden on under the latch. Whilst the latch is tight, its made of rubber and could be tighter. That may help the bonnet shape at the front. Anyway, the rear is only attached via ratchet strap and the nose is only clamped in place:

Pleased although it isn't 100% perfect - not sure if that's even possible, but I will give it a good go once I get my remaining bonnet straps.

Another busy day - off out for some tea and a rest! Holiday next week :D

Sunday, 17 April 2016

Saturday, 16 April 2016

Scuttle Complete

I feel like I've not really done much today but actually spent a solid six hours on the car, I guess its because I've focused more on getting things perfect rather than making progress. This part of the car will be highly visible so a good finish is a must.

After trial fitting the dash mount panel whilst the scuttle was on the car it became obvious it would be a much easier and better job to remove the scuttle again than fit in situe. So, off she came:

Coffee brewed I started from the centre working out, notice the cleco to hold it together:

Each side finished once the scuttle had been re-attached fully in the correct position:

After trial fitting the dash mount panel whilst the scuttle was on the car it became obvious it would be a much easier and better job to remove the scuttle again than fit in situe. So, off she came:

Coffee brewed I started from the centre working out, notice the cleco to hold it together:

That idea was soon scrapped. There just isn't enough material to attach and remove the celecos without some sort of damage, in the end I actually used rivets and glued the tabs three at a time so I still had some flex. I left the end three tabs unattached so I had some flex in the scuttle when re-attached, plan being to finish it in place all lined up (different to what I did with the back panel!):

Nice bead of sikaflex on the inside, easier to do before re-attached. Then I ground down the rear and front of each (countersunk) rivet. I had previously tested normal dome head rivets which I had ground off completely and the strength was still there, combined with the sikaflex I think it will be good enough:

Each side finished once the scuttle had been re-attached fully in the correct position:

Not a rivet in sight:

And the final finish, really pleased with the end result:

The plan was to attach the GRP dash whilst the glue goes off but unfortunately I ordered the none GT version so it doesn't fit! I'll sort a replacement out with GBS next week but for now, I'll call it a day.

Tuesday, 12 April 2016

Scuttle Dash Edge - those rivets!

After discussing this on the forum and chatting at work, the brain wave came to use a template for these rivets. I am not looking forward to putting rivets so close to the edge of a panel - I don't have the most delicate of touches!

I made the template out of a piece of right angled metal from work and after lots of trial and error came up with this method to give me a perfect finish. This was achieved using dome head rivets, I have purchased some countersunk ones and will re-test with them as they may give an even more flush finish.

Here is the template I made:

I mocked up a test in the vice and it worked fine, once drilled through a quick squirt of WD40 and a countersink bit first:

Once riveted I added a small piece of tape to protect the exposed finish, then ground down the head with dremmel, I need a better bit really as the one I used was rather course; although this may not be needed with countersunk rivet:

Underside:

And the finished result:

It looks good, rivet is completely hidden and its strong - even without sikaflex. It seems like a plan to me! Feel more relaxed now, that's me done till the weekend. I think if I spend any more time in the garage I will be banished there for good by the wife! :)

I made the template out of a piece of right angled metal from work and after lots of trial and error came up with this method to give me a perfect finish. This was achieved using dome head rivets, I have purchased some countersunk ones and will re-test with them as they may give an even more flush finish.

Here is the template I made:

All I need to do is attach the trim and draw round the edge:

Attach the tool with two small 25mm G clamps and line up the mark from the panel to the template:

Once riveted I added a small piece of tape to protect the exposed finish, then ground down the head with dremmel, I need a better bit really as the one I used was rather course; although this may not be needed with countersunk rivet:

Underside:

And the finished result:

It looks good, rivet is completely hidden and its strong - even without sikaflex. It seems like a plan to me! Feel more relaxed now, that's me done till the weekend. I think if I spend any more time in the garage I will be banished there for good by the wife! :)

Monday, 11 April 2016

Scuttle Day 2

Lots done today, I am glad I decided to make the scuttle removable as already I have removed it twice!

Nothing too difficult so far, lots of measuring and checking things fit nicely. I also opted for some draft excluder, purchased some decent "P" style from ScrewFix and its a lot better quality than the BNQ stuff. So, M6 rivnuts drilled and inserted in the chassis (ouch! my hands now hurt):

Trial fit, all looks good. Took the firewall off and back indoors to start forming the curve, same process as the rear panel:

Back on the car and time to get the ratchet strap out, without it this would be difficult with only one person:

It took lots of minor adjustments to get everything square and lined up perfectly, I figure anything off at this point will be really noticeable. Finally all bonded with sikalfix and clecos to pull it together:

You can see on this photo the drivers side sags down a little, this will be fine once the inner dash panel goes in - it will all get pulled into shape. After leaving it to go off overnight I started work on the rivets on the front edge of the scuttle, for this I am going to have to go really close to the edge:

My first attempt was somewhat of a fail. I suspect I may have the wrong type of trim - although even if that is correct, I still don't see how they will add much to the structure. I have decided I will glue and revisit once I trial fit the bonnet - that way I know what sort of clearance I have. From what I read, its 1-2cm.

I don't have that luxury on the side facing the rear and that needs to be 100% spot on because I will stare at it whilst driving.

Will leave the front edge like this and then trim + file the tabs down for the front.

Nothing too difficult so far, lots of measuring and checking things fit nicely. I also opted for some draft excluder, purchased some decent "P" style from ScrewFix and its a lot better quality than the BNQ stuff. So, M6 rivnuts drilled and inserted in the chassis (ouch! my hands now hurt):

Trial fit, all looks good. Took the firewall off and back indoors to start forming the curve, same process as the rear panel:

Back on the car and time to get the ratchet strap out, without it this would be difficult with only one person:

It took lots of minor adjustments to get everything square and lined up perfectly, I figure anything off at this point will be really noticeable. Finally all bonded with sikalfix and clecos to pull it together:

You can see on this photo the drivers side sags down a little, this will be fine once the inner dash panel goes in - it will all get pulled into shape. After leaving it to go off overnight I started work on the rivets on the front edge of the scuttle, for this I am going to have to go really close to the edge:

My first attempt was somewhat of a fail. I suspect I may have the wrong type of trim - although even if that is correct, I still don't see how they will add much to the structure. I have decided I will glue and revisit once I trial fit the bonnet - that way I know what sort of clearance I have. From what I read, its 1-2cm.

I don't have that luxury on the side facing the rear and that needs to be 100% spot on because I will stare at it whilst driving.

Will leave the front edge like this and then trim + file the tabs down for the front.

Saturday, 9 April 2016

Final Rear Panel Trimming and Scuttle Day 1

Finished the inside trim around the rear panel and also both arches:

Making some real progress, I've tidied up the wiring loom along the tunnel and plugged in the handbrake sensor, I've left the speedo sensor bracket for now - I don't have the sensor yet so will do that later.

I started on the scuttle - this took much longer than expected because I had to remove the pedal box first as I decided I wanted to make the scuttle and battery tray removable. I can see the benefits of doing this, even though its unlikely I will ever remove it in the future; now is the time to do and it may save me some work later down the line. The downside is I have to do lots of riv nutting and the tool I have is hard work! I took my time and took lots of measurements:

It doesn't look like a whole lot yet, but I've riv nutted everything bar the front edge and it all fits nicely with these low profile M6 bolts:

First thing this morning I cleaned up my steering column - I was win two minds again if this needed doing, but as I am going for a new registration I need to make sure everything is new\as new (technically I am only allowed three things which are second hand):

The finished product tomorrow should be dry enough to fit:

That's me done for today, time for a well earned beer!

Making some real progress, I've tidied up the wiring loom along the tunnel and plugged in the handbrake sensor, I've left the speedo sensor bracket for now - I don't have the sensor yet so will do that later.

I started on the scuttle - this took much longer than expected because I had to remove the pedal box first as I decided I wanted to make the scuttle and battery tray removable. I can see the benefits of doing this, even though its unlikely I will ever remove it in the future; now is the time to do and it may save me some work later down the line. The downside is I have to do lots of riv nutting and the tool I have is hard work! I took my time and took lots of measurements:

It doesn't look like a whole lot yet, but I've riv nutted everything bar the front edge and it all fits nicely with these low profile M6 bolts:

First thing this morning I cleaned up my steering column - I was win two minds again if this needed doing, but as I am going for a new registration I need to make sure everything is new\as new (technically I am only allowed three things which are second hand):

The finished product tomorrow should be dry enough to fit:

That's me done for today, time for a well earned beer!

Sunday, 3 April 2016

Rear Arch Trim

Not much done today, finished the rear boot infill - no pics as, it looks the same as the last one only fixed.

I've also done the passenger side trim above the wheel arch using tadpole trim. It looks absolutely fine from the front and from the rear, but if you look closely there's maybe a 2mm gap between the panel and trim. Like I say, not noticeable but I know its there. I think I've just realised that the car isn't going to be perfect, no doubt other bits are going to come up along the way.

The problem is when I drilled the holes to attach the trim to the chassis I measured the width and drilled perfectly centre to the chassis, rather than lining up the outside edge and drilling from there. It made sense at the time but frustratingly it should be a couple of mm to the left but I have no choice now but to go with it:

I'll conveniently miss the part out where I drilled through the end of my finger with a 3.2mm bit and ended up super gluing it together....

I've also done the passenger side trim above the wheel arch using tadpole trim. It looks absolutely fine from the front and from the rear, but if you look closely there's maybe a 2mm gap between the panel and trim. Like I say, not noticeable but I know its there. I think I've just realised that the car isn't going to be perfect, no doubt other bits are going to come up along the way.

The problem is when I drilled the holes to attach the trim to the chassis I measured the width and drilled perfectly centre to the chassis, rather than lining up the outside edge and drilling from there. It made sense at the time but frustratingly it should be a couple of mm to the left but I have no choice now but to go with it:

The inside looks fine and this will be covered by carpet anyway:

If I get chance tomorrow night I'll try get the drivers side done, run the inside trim around the rear top lip and then I think I'll start on the scuttle.

Saturday, 2 April 2016

Rear Panel - Complete

There wasn't actually that much left to finish - but my god, I feel like I've been on a mission today! 10 hours straight on the car, enjoyed it but some parts were frustrating. First, I didn't think to rivnut the panel at the bottom where the lights are attached. There isn't enough room between the tank and the panel to fit a rivnut, change of plan. I taped a spanner to a small sheet of aluminium and padded the end of the spanner out with tape so the nut wouldn't drop off.

After around an hour (yes, that's right, an hour) I managed to fit the reverse light. Next was the fog light and that turned out to be an absolute nightmare. I purchased the ready modified version from GBS, however, the hole for the wire is on the right hand side, yet the wire comes out of the panel on the left:

I am not sure if this is expected but it seems stupid to me. Maybe they are both like that so they are interchangeable (I guess cheaper to produce) but it would make more sense for GBS to put the hole for the wire on the right, for the fog light; they are pre drilled. Not a big problem, but a pain because the wires are ran to length and already terminated.

Queue the soldering iron, shrink wrap and some patience:

Neat job and enough length for the wire to travel across the top of the light. Great, all done:

The plate light was easy to do as its at the top of the fuel tank, again though, the design seems a little odd to me. There simply isn't enough room for the spades and wires to connect and the fitment to attach. I managed to get it on, but I'm not 100% happy and will likely revisit it and re-terminate the wires with better\different connectors.

I've fitted my fuel cap:

And also started on the boot infil panels and fitted the fuel level sender - the right hand panel does not fit correctly, its no where near. The left however does and the tank is central, which makes me think the panel is not right but I'll work with it.

One final annoying thing - the easy fit loom I purchased has all the spades and connectors attached, which is great. Apart from a couple - the rear light clusters. They have to fit through a hole each side in the rear panel, that's not possible. I had to grind down an old nail to unclip each, pass through and put a grommet in, then re-attach:

No biggie but when you are tired at the end of the day, it's a PITA! Tomorrow I will spend some more time on the rear infils and do some final fettling so I am 100% happy before moving on.

After around an hour (yes, that's right, an hour) I managed to fit the reverse light. Next was the fog light and that turned out to be an absolute nightmare. I purchased the ready modified version from GBS, however, the hole for the wire is on the right hand side, yet the wire comes out of the panel on the left:

I am not sure if this is expected but it seems stupid to me. Maybe they are both like that so they are interchangeable (I guess cheaper to produce) but it would make more sense for GBS to put the hole for the wire on the right, for the fog light; they are pre drilled. Not a big problem, but a pain because the wires are ran to length and already terminated.

Queue the soldering iron, shrink wrap and some patience:

The plate light was easy to do as its at the top of the fuel tank, again though, the design seems a little odd to me. There simply isn't enough room for the spades and wires to connect and the fitment to attach. I managed to get it on, but I'm not 100% happy and will likely revisit it and re-terminate the wires with better\different connectors.

I've fitted my fuel cap:

And also started on the boot infil panels and fitted the fuel level sender - the right hand panel does not fit correctly, its no where near. The left however does and the tank is central, which makes me think the panel is not right but I'll work with it.

One final annoying thing - the easy fit loom I purchased has all the spades and connectors attached, which is great. Apart from a couple - the rear light clusters. They have to fit through a hole each side in the rear panel, that's not possible. I had to grind down an old nail to unclip each, pass through and put a grommet in, then re-attach:

No biggie but when you are tired at the end of the day, it's a PITA! Tomorrow I will spend some more time on the rear infils and do some final fettling so I am 100% happy before moving on.

Subscribe to:

Comments (Atom)